- A new nanostructured copper alloy, Cu-Ta-Li, has been developed by U.S. ARL and Lehigh University researchers.

- It offers strength and thermal stability comparable to nickel-based superalloys.

- The alloy maintains copper’s high thermal and electrical conductivity at extreme temperatures.

- The breakthrough involves a unique complexion-stabilized nanostructure.

- Potential applications include aerospace, defense (hypersonics, engines), and industrial sectors.

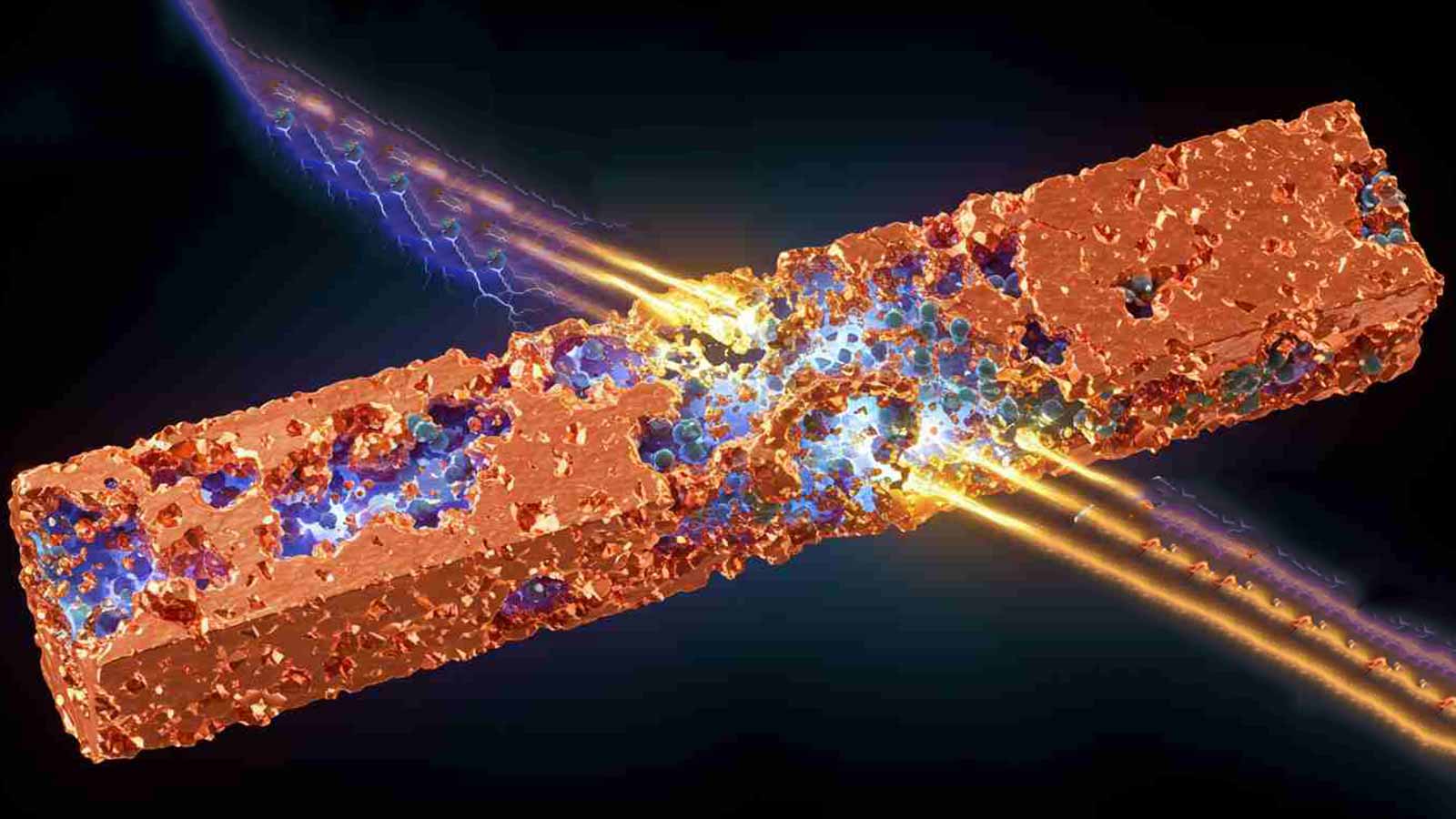

Researchers from the U.S. Army Research Laboratory (ARL) and Lehigh University have developed a groundbreaking nanostructured copper alloy that exhibits strength comparable to superalloys while maintaining copper’s inherent conductivity. This new material, a Cu-Ta-Li (Copper-Tantalum-Lithium) alloy, could potentially redefine high-temperature materials for various advanced applications. Their findings were published in the journal Science on April 11, 2025.

Breakthrough Material Properties

The Cu-Ta-Li alloy demonstrates exceptional thermal stability and mechanical strength, positioning it among the most resilient copper-based materials created to date. It can withstand extreme heat without significant degradation and resists deformation even near its melting point. Martin Harmer, a co-author of the study, described the material as one that “uniquely combines copper’s excellent conductivity with strength and durability on the scale of nickel-based superalloys.” (Source: News Report by ARL and Lehigh University)

How the Alloy Achieves High Strength at Temperature

The key to the alloy’s remarkable high-temperature performance is attributed to a unique complexion-stabilized nanostructure. This involves the formation of Cu₃Li precipitates, which are stabilized by a Ta-rich atomic bilayer complexion. This complexion acts as a structural stabilizer, preventing grain growth at high temperatures, unlike typical grain boundaries that would migrate over time. This concept was pioneered by the Lehigh researchers. (Source: News Report by ARL and Lehigh University)

Potential Applications and Significance

By merging the high-temperature resilience typically found in materials like nickel-based superalloys with copper’s exceptional conductivity, this new alloy opens possibilities for next-generation applications. These include heat exchangers, advanced propulsion systems, and thermal management solutions for cutting-edge missile and hypersonic technologies. Harmer noted the alloy provides “the foundation to create new materials for hypersonics and high performance turbine engines.” While not a direct replacement for traditional superalloys in ultra-high temperature uses, its unique combination of properties allows it to complement them in advanced engineering solutions, with strategic significance particularly in defense. (Source: News Report by ARL and Lehigh University)

Research Team and Collaboration

The development of the alloy was a collaborative effort involving researchers from ARL, Lehigh University, Arizona State University, and Louisiana State University. Christopher Marvel, a professor at Louisiana State University and an author on the paper, highlighted Lehigh’s strength in electron microscopy, stating it was “really key to understanding the material.” Joshua Smeltzer, a Lehigh alum now at Honeywell, also contributed to the research using Lehigh’s state-of-the-art Atomic Resolution Microscope (ARM) to analyze the material at atomic scale. (Source: News Report by ARL and Lehigh University)

Testing and Future Work

The alloy was synthesized using powder metallurgy and high-energy cryogenic milling and underwent rigorous testing to confirm its properties. This included 10,000 hours (over a year) of annealing at 800°C to test long-term stability, advanced microscopy techniques, and creep resistance experiments. Computational modeling was also utilized to validate the stabilizing mechanism. Future research plans include directly measuring the alloy’s thermal conductivity compared to alternatives, preparing it for potential applications, and developing other high-temperature alloys based on this new design strategy. (Source: News Report by ARL and Lehigh University)

Patent and Funding

The U.S. Army Research Laboratory has been awarded a U.S. patent (US 11,975,385 B2) for the alloy, underscoring its strategic significance, particularly for defense applications such as military heat exchangers, propulsion systems, and hypersonic vehicles. The research was supported by a $25 million cooperative agreement between Lehigh and ARL, alongside funding from the National Science Foundation and Lehigh’s Presidential Nano-Human Interfaces (NHI) Initiative. Martin Harmer emphasized that such federal investment in fundamental science is key to strengthening national security and fueling industrial innovation. (Source: News Report by ARL and Lehigh University)